Efficiency measurement

"You can't improve what you can't measure."

Many customers have the same question:

"We pay good money for an energy conservation project, but can you guarantee the economic benefits you claim?"

If it is possible to calculate and compare the electricity cost BEFORE and AFTER the implementation of energy efficient technologies using objective control, there is no reason to believe in guarantees.

Answer:

"Any company that implements energy conservation projects should be responsible for the end result!"

We fully agree with the rule:

Our engineers developed and successfully launched an electricity metering platform. It helps build an efficiency measurement system for almost any process in the food industry, including the refrigeration system.

Objective control systems to measure efficiency in real time:

ambient air temperature

COP Hunter®

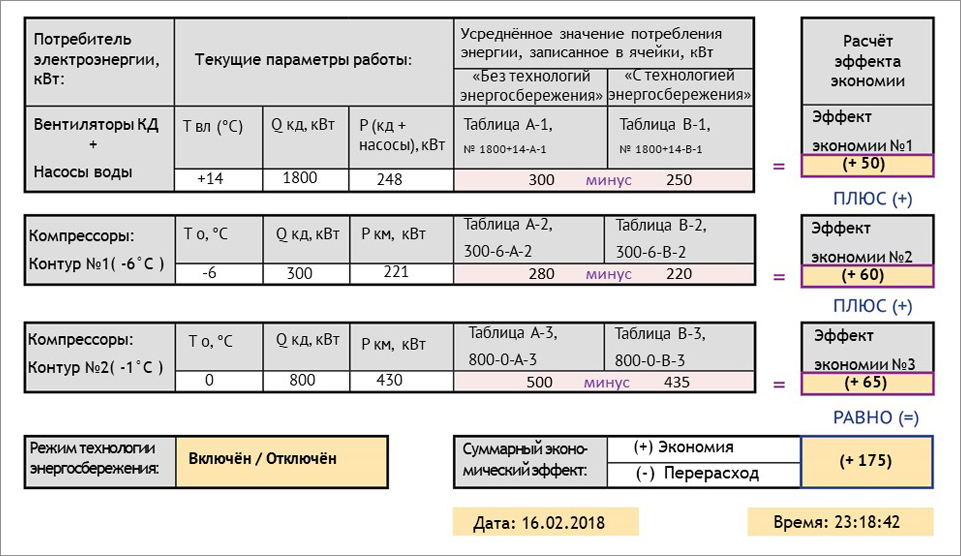

The user has access to all the necessary information during the operation of the COP Hunter® system, which enables the customer to record and compare in real time the energy consumption of the refrigeration system BEFORE and AFTER the implementation of energy efficient technologies.

automatic energy efficiency meter for industrial refrigeration systems

The system compares the electricity consumption per unit of cold produced BEFORE and AFTER the implementation of the energy efficiency project, considering the variability of the parameters required for the analysis, such as:

heat load of the main production facility

Applied

to measure the efficiency after the implementation of energy efficient technologies

1

2

Carbon Steps®

The user has access to all the necessary information during the operation of the Carbon Steps® system, which allows the customer to record and compare in real time the energy consumption of the measured production unit BEFORE and AFTER the implementation of a project aimed at reducing the consumption of electricity or other energy resources.

for various processes in the food industry

The system compares the electricity consumption per unit of product produced (heat, company products, etc.) BEFORE and AFTER the implementation of the energy efficiency project, considering the variability of operating parameters that affect the increase or decrease of electricity consumption.

Applied

to measure the efficiency after the implementation of energy efficient technologies